Filquip is the Australian distributor and agent for Air-Tec Systems and the Queensland agent for WAM products and Equipment allowing a diverse range of diverter valves for pneumatic conveying systems.

Air-Tec DEV High Pressure Oscillating Tube Diverter Valve

Air-Tec DEV High Pressure Oscillating Tube Diverter Valve

The Air-Tec DEV diverter valves are certified for pressure up to 6 bar.

- Available in the 2 and 3 way versions.

- Available in sizes from 2” to 6” with contact parts in carbon steel or AISI 304.

- Robust and resistant cover that allows for both indoor and outdoor operation.

Suitable for handling materials of any size including with abrasive or fragile materials, as well as those that tend to clog.

An inflatable seal placed on the head of the oscillating tube is deflated when the tube changes its position and inflates again after the pipe has reached the desired position which is controlled by limit switches.

WAM Gravity Diverter Flap Valve DVA

WAM Gravity Diverter Flap Valve DVA

The DVA Diverter flap valves are for diverting gravity flow of material from one source to two destinations.

- Manufactured from aluminium alloy with SINT engineering polymer lining.

- Manual, Pneumatic or Electrical actuation options available.

- Food grade version available.

The DVA comes in 175, 225, 275 and 325mm square internal inlet and outlet sizes.

Open DVA Gravity Flag Diverter Brochure

TOREX Pipeline Flap Diverter Valve VAB

TOREX Pipeline Flap Diverter Valve VAB

The VAB pipeline flap diverter valves use a swinging flap of wear resistant EPDM rubber to divert pneumatically conveyed material from one source between two destinations.

- Manufactured body from aluminium alloy.

- Manual, Pneumatic or Electrical actuation options available.

- The flap is Food grade, Antistatic and Wear resistant.

- Working Pressure up to 2 bar.

The VAB Pipeline Flap Diverter Valve comes in 50mm, 65mm, 80mm, 100mm, 125mm, 150mm, and 200mm diameter sizes.

View the TOREX Diverter Valves specifications datasheet and brochure

Open VAB Flap Diverter Brochure

TOREX Compact Oscillating Diverter Valve VAD

TOREX Compact Oscillating Diverter Valve VAD

The VAD compact oscillating diverter valve moves the internal pipe between to destination outlet pipes.

- Manufactured body from aluminium alloy.

- Nickel plated option for additional wear resistance.

- Manual, Pneumatic or Electrical actuation options available.

- Working Pressure up to 2.5 bar.

The VAD oscillating diverter valve comes in 50mm, 80mm and 100mm diameter sizes.

View the TOREX Diverter Valves specifications datasheet and brochure

Open VAD Diverter Valve Brochure

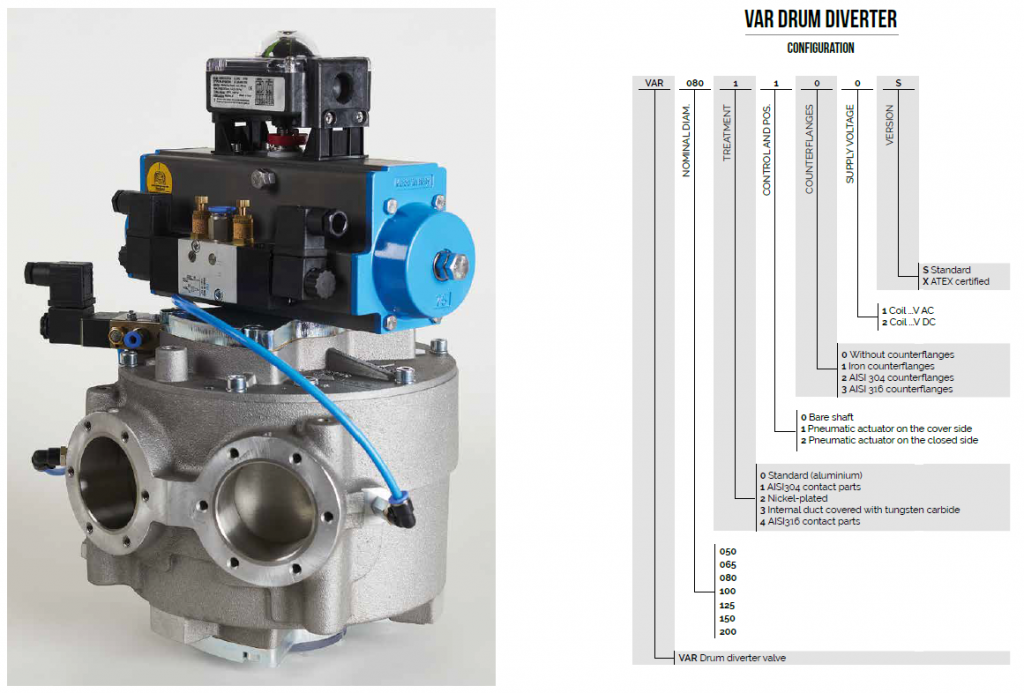

TOREX Drum Diverter Valve VAR

TOREX Drum Diverter Valve VAR

The VAR drum type diverter valve uses a pneumatic actuator to rotate the inner drum and commutation of the discharge pipeline face producing a seamless diversion of material between pipelines.

- Manufactured body from aluminium alloy or Stainless steel.

- Nickel plated and Tungsten carbide options available for additional wear resistance.

- Manual, Pneumatic or Electrical actuation options available.

- Working Pressure up to 3.5 bar.

The VAR drum type oscillating valve comes in 50mm, 65mm, 80mm, 100mm, 125mm, 150mm, 175mm and 200mm diameter sizes.

View the TOREX Diverter Valves specifications datasheet and brochure

Open VAR Drum Diverter Valve Brochure

TOREX Plug Diverter Valve VAS

TOREX Plug Diverter Valve VAS

The VAS plug diverter valves use a pneumatic actuator to rotate the inner pipeline pathway enabling positive and negative pressure pneumatic conveying in any direction.

- Manufactured body from aluminium alloy.

- Nickel plated versions available.

- Diverter angle 60 deg.

- Minimum exchange time 3 seconds.

- Working Vacuum Pressure: -0.5 bar vacuum

- Positive Pressure Conveying: + 1 bar gauge

- Available in Hazardous Area Configurations

The VAS plug type diverter valve comes in 50mm, 65mm, 80mm, 100mm, 125mm, 150mm and 200mm diameter sizes.

View the TOREX Diverter Valves specifications datasheet and brochure

Open Plug Diverter Valve Brochure

TOREX Pinch Valve VM

TOREX Pinch Valve VM

The Pinch valve provides a valve seal which does not impede pneumatic conveying flow and is not as affected by the abrasive wear of pneumatic conveying.

- Available in sizes of 0.5”, 0.75”, 1”, 1.25”, 1.5”, 2”, 2.5”, 3”, 4”, 5”, 6” and 8” diameter.

- Industrial or Food grade versions available.

The Pinch valve is operated by introducing compressed air into the threaded bore of the valve interior, the internal flexible sleeve is shaped to hermetically seal the passage.

View the Pinch Valves specifications datasheet and brochure

Pinch Valve Control Panel

Pinch Valve Control Panel

The pinch valve control panel allows pinch valves to be used as diverter valves for pneumatic conveying lines. The panel operated a set of solenoid air valves that open and close the respective valves on the conveying pipeline to define the path to the required destination location.

Magnetic Separators and Tube/Pipe Magnets

The Magnetic Separators and Tube/Pipe Magnets are available from Filquip including manual and automated metal disposal from options for your system.

The automated magnetic separators work by magnetising metals contained in the product flow which become held to the side wall magnet, the side wall magnet flap then opens with the metals still magnetised, with the magnetic flap open over the discharge chute demagnetisation occurs depositing the metals into the waste chute.

The automated magnetic separators come in three standard sizes:

- 200mm x 350mm (Throughput 100 m3/hr)

- 200mm x 650mm (Throughput 200 m3/hr)

- 200mm x 950mm (Throughput 300 m3/hr)

The manual tube/Pipe Magnets are designed to intercept metals contained in the product flow and hold them to the magnetic body for cleaning and disposal. The tube or pipe magnets come in eight standard sizes:

- 100mm Diameter (Throughput 10 m3/hr)

- 150mm Diameter (Throughput 35 m3/hr)

- 200mm Diameter (Throughput 85 m3/hr)

- 250mm Diameter (Throughput 130 m3/hr)

- 300mm Diameter (Throughput 200 m3/hr)

- 400mm Diameter (Throughput 260 m3/hr)

- 500mm Diameter (Throughput 310 m3/hr)

- 600mm Diameter (Throughput 400 m3/hr)

Open the Magnetic Separators and Tube/Pipe Magnets Brochure