Filquip has designed and supplied a new Alumina Tri-Hydrate Bulk Bag Decanter with weighing system to automate the bulk bag unloading process for a customer so the correct weight of product is decanted from the screw conveyor on the bulk bag decanter into a mixing tank.

When required, the plant PLC specifes the weight of alumina needed in the mixing tank. The load cells on the system provide loss in weight feedback to help control the screw conveyor which meters out the Alumina from the bulk bag until the correct weight has been decanted into the tank.

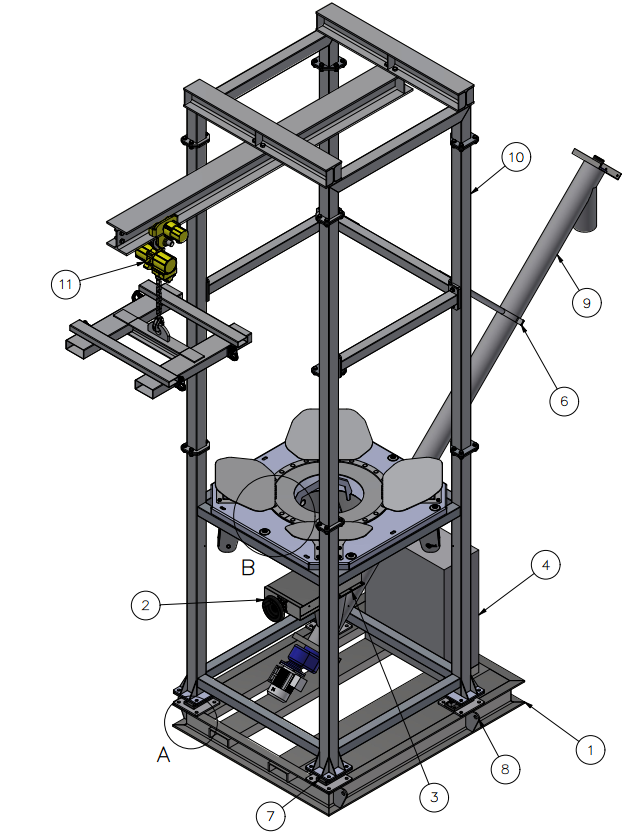

The following Filquip equipment package was provided for this system:

- SBB-HFF-M Bulk Bag Decanter with Monorail and 2T Electrical Crane Hoist

- Bulk Bag Massaging System for improved product flow out of each bulk bag

- Manual Isolation Slide Gate Valve between the bulk bag unloader and the Screw Conveyor

- TX SS304 Screw Conveyor, 150mm Diameter, 3700mm long with 250mm flared and extended inlet cone

- Support Skid Frame in SS304 PFC with integrated Load Cells, Summing Box and Weight Indicator

- Integrated Control Panel with Local and Remote Operation modes