Filquip is the Australian distributor and agent for Air-Tec Systems and their patented dense phase conveying transporters which guarantee reliability and safety during the transportation of foods, as well as fragile, abrasive, toxic, plastic and lumpy materials. Dense Phase Conveying which can also be known as pressure pot pneumatic conveying is an effective solution to move difficult and abrasive products.

Open Filquip Dense Phase Systems Brochure

BART Dense Phase Conveying System

BART Dense Phase Conveying System

The BART Dense Phase Conveying System is able to transport materials that tend to clog or are abrasive and is particularly suitable for humid places, as well as food, chemical or pharmaceutical industries.

- Distances up to 20m.

- Capacity up to 1 ton/h.

- Pressure up to 2 bar.

- Vessel capacity 24L.

- 150mm Diameter Inlet Valve.

- Transport pipeline outlet options 1.5”, 2” and 3” diameter.

- Available in ATEX Zone 22, ATEX Zone 21, Carbon steel, Stainless steel 304 or 316.

There is also a High Temperature (HT) version for the transport of materials up to 250° C such as ashes and slag.

BART-One Dense Phase Conveying Systems

BART-One Dense Phase Conveying Systems

The BART-ONE Dense Phase Conveying systems pneumatically convey products at high flow rates at around 25% of the speed of lean phase blow conveying, resulting in reduced pipe wear, less product stratification (keeping mixed products together) and reduced energy consumption.

- Distances up to 70m.

- Capacities from 3 to 20 ton/h.

- Pressure up to 6 bar.

- Vessel capacities of 80L, 150L, 300L, 600L & 900L.

- 200/250 mm Diameter Inlet Valve.

- Transport pipeline outlet options 2”, 3”, 4”, 5” & 6” diameter.

- Available in ATEX Zone 22, ATEX Zone 21, Carbon steel, Stainless steel 304 or 316.

All BART-One Dense Phase Systems are equipped with an advanced control system to manage the introduced air.

There is also a High Temperature (HT) version for the transport of materials up to 250° C such as ashes and slag. Bart-One vessels are certified according to the PED – European Pressure Equipment Directive and are certified to Australian Standard for Pressure Vessels.

TPA Dense Phase Conveying System

TPA Dense Phase Conveying System

The TPA Dense Phase Conveying System is a first class solution for abrasive, fragile and difficult to convey materials and includes an advanced electronic control system to enable a larger flexibility of application and a better control of the transport cycle as well as inbuilt selectable control for conveying to many destinations.

- Distances up to and beyond 500m.

- Capacities up to 100 ton/h.

- Pressure up to 7 bar.

- Vessel capacities from 80L to 4,428L.

- 200/250/300 mm Diameter Inlet Valve.

- Transport pipeline outlet options 2”, 3”, 4”, 5”, 6” & 8” diameter.

- Available in ATEX Zone 22, ATEX Zone 21, Carbon steel, Stainless steel 304 or 316.

With the use of boosters, the TPA system guarantees the integrity of the materials during transport without stratification (keeps mixed products such as PVC or cementitious blends together). TPA vessels are certified according to the PED – European Pressure Equipment Directive and Australian Standards and all come with Australian Pressure Vessel Certification. There is also a High Temperature (HT) version for the transport of materials up to 250° C such as ashes and slag.

The TPA Dense Phase Systems allow three types of conveying modes depending on the required method of transport:

Standard – The line of transport is emptied and purged after each conveying cycle.

Full pipeline – Material is conveyed in a full pipeline operation. This permits air and energy saving compared with the conventional method. The TPA full pipeline transporters are used to move fragile materials as the material flow is constant. The system starts and stops with a full line and can have automation control to purge if required.

Full pipeline continuous – The use of two TPA full pipeline transporters connected allows constant conveying of the material without a pause for loading time. The vessels operate in tandem where one vessel conveys the material while the other loads achieving large flow rates that can exceed 100 tons/h.

Dense Phase Materials Conveyed

Dense Phase Materials Conveyed

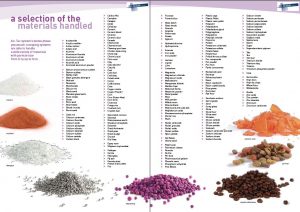

The Air-Tec Dense Phase systems can transport a large range of materials. Filquip has a mobile trial dense phase unit which can be used to test the conveying of any material you may have.

Selection of Materials Handled

Diverter Valves

Diverter Valves

Filquip supplies a range of in pipeline diverter valves in a range of mechanical operating layouts (Drum Type, Flap type, Pinch Valves, Oscilating Pipe Type etc). From 2” to 8” in size and diverting from 1 inlet to 2 outlets all the way up to 1 inlet with 10 outlets.

Air boosters

Air boosters

When installed along the conveying line the air boosters add the optimal amount of additional air at the optimal locations along the line.

- Reduces wear during pneumatic conveying.

- Controls conveying flow rate.

- Reduces overall pneumatic conveying air consumption.

- Maintains aeration of product in the pipeline.

Air Boosters act like many helping hands along the conveying pipeline to help the product move along.

Eurac Pipe Couplings

Eurac Pipe Couplings

Filquip is an Australian distributor for Eurac clamps for pipe and tube.

- Sizing from 38.1mm to 300mm in diameter.

- Suitable for all pneumatic and vacuum conveying operations.

- High working pressure.

- Available in Galvanised steel with Stainless Steel contact parts or in full Stainless Steel.

- NBR seals supplied as standard, other options includes FDA approved food grade, Viton and Silicon seals.

EXTRAC Bulk Bag Unloader SBB

EXTRAC Bulk Bag Unloader SBB

The SBB Bulk Bag unloader provides an effective solution to unloading bulk bags of product in an efficient manner.

- Available in a half frame height where a crane or forklift is utilised to lift and hold the bag during unloading

- Available in full frame height with telescopic rails for bag loading with a forklift into the frame.

- Includes a vibrating pan plate and dust collection point to ensure efficient and clean bulk bag unloading.

- Bulk Bag Unloaders are available in Carbon Steel, Stainless Steel 304 and Stainless Steel 316.

EXTRAC Lump Breakers

EXTRAC Lump Breakers

Filquip provides a range of lump breakers and crumblers for breaking up lumpy materials.

- Twin shaft for high throughput rates.

- Available in Carbon steel, Stainless steel 304 & 316.

- Throughputs up to 50m³ / hr.