Hazardous Area IECEX Brewery Grain Vacuum Conveying System

Filquip has specified, supplied, installed and commissioned a Hazardous Area IECEX Brewery Grain Vacuum Conveying System (ExtD). The design transports 2.5TPH of malted barley brewery grain using a vacuum conveying system which draws the product from one of two storage silos and transports it 30m through a number of bends into the brewery mill.

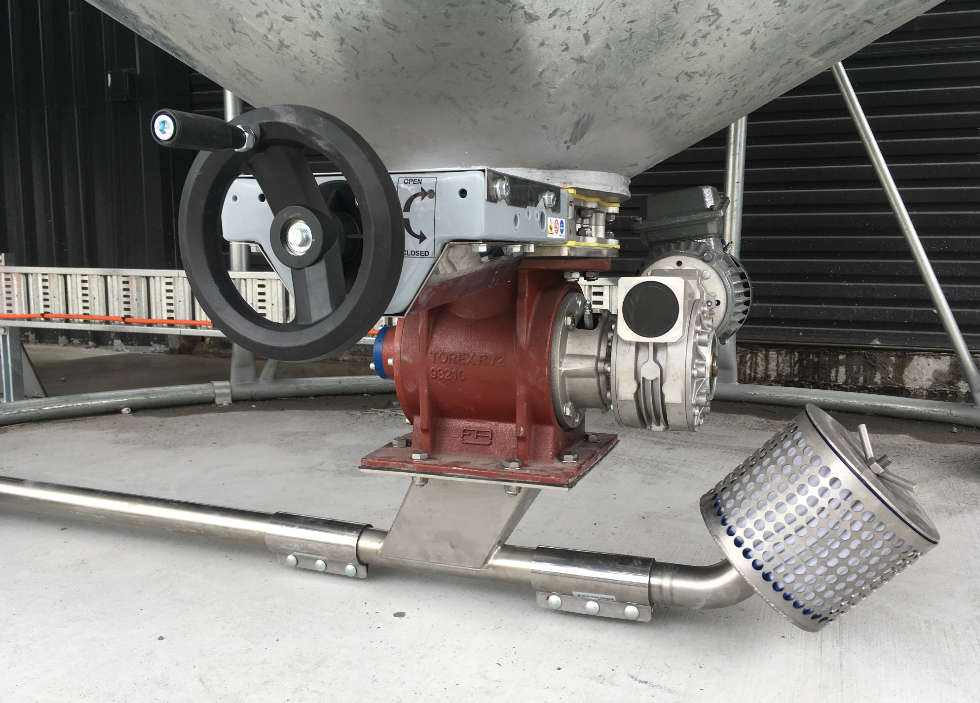

The following equipment package was supplied and Installed by Filquip:

- 5kW Vacuum Blower System.

- Three Drop Through Rotary Valve (Model RVR02.20, 0.55kW IECEX ExtD Motor).

- Two Borosilicate Sight Glasses (50.mm OD, 500mm long).

- Vacuum Receiver Separator Filter with Hopper (FNS3J22D).

- Receiver Silo Explosion Protection Panel(s).

- Receiver Load Cells for weighing product into the mill.

- System control box and HMI for inputting the desired weight of grain to be vacuum conveyed and milled.

The installation of this system has allowed the brewery to buy their grain in bulk as opposed to the previous 25kg bags adding a considerable cost saving to the raw materials. The new system is also automated so plant operators are not manually handling the 25 kg bags of grain.

Given the hazardous area dust explosion risks associated with grain handling. Filquip supplied this vacuum conveying system with IECEX Zone 21 ExtD Rated Instrumentation and ATEX rated mechanical equipment such as rotary valves and dust collectors which were specified with compliant Explosion Resistant Pred pressure specifications to match the sized explosion protection panels.

View the Filquip Vacuum Conveying Range