Filquip offers a range of industrial water treatment equipment including Liquid filter vessels and bags, Externally and internally fed rotating screens, Filter presses and PH neutralisation systems.

Liquid Filters

Liquid Filters

Filquip supplies a large range of liquid filters including needle felts, nylon strainer mesh and metal strainer mesh. P1, P2, P3 & P4 Pong filter bag types available in a Polyloc top or Steel ring configuration.

Filquip supplies liquid filtration equipment and housings in Polypropylene, Carbon steel, Stainless steel 304 & 316 as well as Titanium and Hastelloy C options.

Solids-Liquids Separators

Solids-Liquids Separators

Filquip offers a range of Solids-Liquids separators for animal waste including the SEPCOM unit specifically designed for dewatering animal manure and biogas digestate to obtain re-useable water or water that meets municipal standards for release.

- Suited to Fruit, Vegetable and Slaughter waste.

- Separates the slurry to re-useable water and solid phases, the solid phase can be used as an odourless fertiliser.

- Available in screen sizes down to 250 micron for throughput rates up to 65m³ / hour.

Open SEPCOM Cattle Manure Brochure

Open SEPCOM Pig Manure Brochure

SPECO Microfilter MFT

SPECO Microfilter MFT

The MFT Microfilter is designed to be integrated into a filtration system to allow filtration of the liquid phase down to a micro level.

- Available in screen sizes of 0.015, 0.025 & 0.05mm.

- Throughput capacity of 10m³ / hr with fluids containing less than 10% dry material.

- SEPCOM Submersible chopper pumps and agitators are also available.

WAM Chemical Dosing Microbatch Feeders MBF

WAM Chemical Dosing Microbatch Feeders MBF

The MBF range of Micro-batch feeders provide accurate volumetric feeding of powder and granular materials.

- Stainless steel body, Agitator tool and Feeder screw.

- Available with Horizontal or Vertical spout outlets.

- Available with food-grade and ATEX zone versions.

- Throughputs of up to 6m³ / hr.

- Integration with a loss in weight system or VSD can provide automated accurate batching systems.

SAVI Rotary Screens

SAVI Rotary Screens

Filquip offers a range of internally and externally fed rotary screens for industrial and municipal waste water treatment.

- RTV Internally Fed Rotary Screens with media screening from 1 to 6mm. Designed for connection to pipework for screening liquid flows to up 360L/S.

- SGR Externally Fed Rotary Screens with media screening from 1 to 6mm. Non-channel flow applications for screening liquid to up 580L/S. Available with and without overflow.

- Systems are both self-cleaning with spray nozzles.

Open Externally Fed Drum Screens Brochure

Open Internally Fed Rotation Drum Screens Brochure

SPECO Screw Compactor / Screenings Compactor

SPECO Screw Compactor / Screenings Compactor

Filquip offers a range of Speco screw compactors and for industrial and municipal waste water treatment.

- The shafted washer compactor can reduce screenings by up to 65% of their volume at a flow rate up to 6m³/hr.

- Available in Stainless Steel 304 and 316.

- Bagger option available.

Open Screenings and Washer Compactor Brochure

Speco Screw Screens

Speco Screw Screens

Filquip offers a range of screw screens for in-channel, in-tank or connecting pipework applications.

- The GCP in-channel screw screen provides solids extraction from the waste water stream at a flow rate up to 270 L/S in channel sizes between 300 to 850mm.

- The GCPC pipework flow screw screen provides solids extraction from the waste water stream at a flow rate up to 270 L/S with Inlet pipe sizes between 200 – 350mm diameter.

- Available in Stainless Steel 304 and 316.

Open In-Piping Screw Screen Brochure

Open Vertical Screw Screen Brochure

Grit Separators DS

Grit Separators DS

The Grit Separator controls the flow of the waste water to allow sedimentation of the sand and grit from the stream. The outloading screw conveyor then discharges the grit through the upper outlet.

- Flow Rates up to 10L/s.

- Solids through put up to 1.29 m³ / hour.

- Available in Fluid Dynamic Model for sand separation down to 200 microns.

- Available in Stainless Steel 304 or 316.

Open Fluid Dynamic Grit Classifier Brochure

Shaftless Screw Conveyors SSC

Shaftless Screw Conveyors SSC

Filquip supplies a large range of WAM trough screw conveyors available in shafted and shaftless configurations including and high temperature options.

- Trough screw diameters of 150, 200, 250, 300, 350, 400, 500 and 600mm.

- Numerous inlet and outlet options including spigot, round and square flanges and universal.

- Standard or custom built screw conveyors including options for multiple inlets and outlets, liners and wear bars, reversible operation and with inspection hatches as required.

- Throughputs of up to 100m³ / hr.

Open Shaftless Spiral Conveyor

RONCUZZI Hydrodynamic Screws – Renewable Energy Production PAE

RONCUZZI Hydrodynamic Screws – Renewable Energy Production PAE

The RONCUZZI PAE Hydrodynamic Screw is designed for the production of electric energy from the moving of water.

- Power can be generated from water level drops as low as 1m in height.

- A single screw can produce up to 350 kWh.

- High efficiency with low environmental impact offering vast possibilities of application wherever flowing water can be utilised.

Open Hydrodynamic Screws Brochure

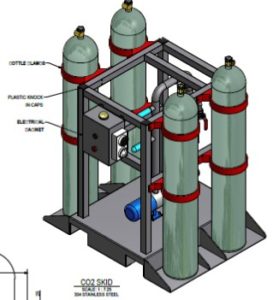

CO2 PH Neutralisation System

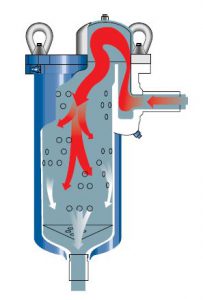

The CO2 PH neutralisation skid use a sparging system to neutralise high alkali (High PH) waters contaminated with Calcium Hydroxide from cement and concrete processes.

- Neutralisation of water from up to PH 13 down to between 6.5 – 7.5.

- Allows reuse of high alkali water from the concrete batching processes.

- Creates a self-buffering reaction (PH cannot drop below 6.5).

- Requires no handling of hazardous liquids.

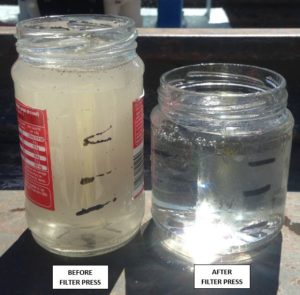

Filter Presses

Filter Presses

Filquip is a supplier of filter press systems including manual, semi-automatic and automatic operation models. The filter press allows solids/liquids seperation of suspended fines with recovery of the solids product in the form of pressed cake plates.

- Pressing force up to 20MPa to avoid leakage.

- Up to 120m2 of filter area.

- Filquip is a supplier of filter press cloths in many varieties and sizes.

Savi Septage Receival Station

Savi Septage Receival Station

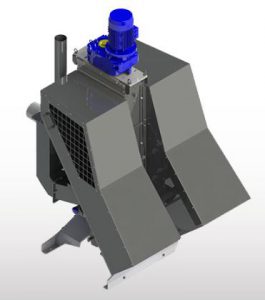

The VFA DM is a septage receival station consisting of a dual motor drive system, perforated plate drum screen complete with screw conveyor and compaction zone, all installed in a tank for connection to pipework or septic tanker trucks. Named “The Beast” by the engineers who created the system for its ability to to handle all items thrown at it including rocks.

- Solid wastes are separated, washed and compacted.

- Self cleaning screen and dewatering zone.

- Three sizes available for a range of flow rates up to 200,000 L/hr

- Available in 304L Stainless Steel or 316L Stainless Steel

Open Savi VFA DM Septage Reciever Station Brochure