Filquip is a supplier of stocked PAC Vacuum Loaders and custom made PAC dosing systems. Our PAC Vacuum loaders are used to convey bags of PAC into a storage hopper or mixing tank. The system uses a suction wand which allows the staff to vacuum load the PAC without the risk physical injury through incorrect lifting techniques and being a vacuum system minimises dust.

News

Breather Bag Dust Socks

Filquip is a supplier of breather bag dust socks for hoppers and silos. Filquip can also provide a base ring upstand with cage to mount the breather sock onto your hopper or silo with a threaded, Tri-Clover, Flanged or Clamped connection type.

25kg Bag Handling Station with Dense Phase Conveyor

Filquip recently delivered and commissioned a new 25kg Bag Break Station paired with a Dense Phase Conveyor for a client, streamlining the transfer of milk powder, cocoa powder, sugar, coconut powder, and various other food ingredients into their site mixer.

Previously, the process required three staff members operating from a mobile ladder platform to manually load 25kg bags into the mixer. The new system enhances efficiency by enabling a single operator to handle the loading process while eliminating the need for a ladder, improving workplace safety.

The innovative Filquip system design integrates the bag break station’s dust extractor to also serve the bag packing head through a pipework and valve system, offering a cost-effective solution by eliminating the need for a separate dust extraction unit within the room for the packing process.

Key equipment supplied includes:

- WAMGroup SS304 RSM Manual Bag Break Station, ATEX-compliant with IECEX pulsing coils, 1.1kW IECEX fanset for integrated dust control, and a Zone 20 internal rating.

- Air-Tec Systems BARTOne 50 Dense Phase Conveyor in SS304, upgraded with IECEX Zone 20 internal instrumentation.

- OLI Vibrators OT16 Pneumatic Vibrator and VBSMI Mini Blue Food-Grade, Metal-Detectable Aerators to enhance flow in the RSM hopper.

- Stainless steel long-radius tube bends for durability and performance.

This solution showcases Filquip’s commitment to efficiency, safety, and cost-saving innovation!

Magbase Magnetic Vibrator

The MagBase Heavy Duty magnetic vibrator mounting bracket is available from Filquip. The MagBase HD is made from Stainless Steel 304 and uses strong rare earth magnets to hold the vibrator against the steel formwork, hopper walls, silos or bins requiring vibrating.

The MagBase handle allows easy movement of vibrators around the steel structure being vibrated and also provides protection for the air fittings on the vibrator from being accidentally damaged.

The Oli range of Pneumatic vibrators are available for direct mounting to the MagBase includes the OR100, OT36S, OT36, OT30, S36 or S30.

Filquip has produced the following video to show the ease of attaching the magbase vibrator to a silo or hopper and its operation.

Red Lead Oxide Vacuum Conveying and Dosing System

Filquip and our partners have recently designed and supplied a Red Lead Oxide Vacuum Conveyor with Storage and Dosing Hopper. Highlights of the project equipment package include

- 11kW Vacuum Generator with Secondary Hi-Protection Filter Chamber to mitigate red lead dust emissions.

- WAM FPNHD12 Insertable Dust Collector, Negative Pressure Build with PTFE coated filters.

- SS304 Custom fabricated hopper with 400L active storage capacity.

- TOREX RVR02.10 Rotary Valve, 10RPM with 0.55kw Motor for dosing control from the hopper.

- Load Cells for loss in weight feedback when dosing.

- Vacuum Wand System with Bypass airlflow valving for when the reciever hopper has reached the target weight and the conveying line and purge.

For your custom designed and built vacuum conveying and dosing systems please contact Filquip

Filquip Magnetic Vibrator Mounts

Another delivery of our in stock Filquip MagBases with OLI OR100 Pneumatic Vibrators getting packed to ship to one of our customers.

The MagBase Heavy Duty magnetic vibrator mounting bracket is available from Filquip. The MagBase HD is made from Stainless Steel 304 and uses strong rare earth magnets to hold the vibrator against the steel formwork, hopper walls, silos or bins requiring vibrating.

The MagBase handle allows easy movement of vibrators around the steel structure being vibrated and also provides protection for the air fittings on the vibrator from being accidentally damaged.

The Oli range of Pneumatic vibrators that are available for direct mounting to the MagBase includes the OR100, OT36S, OT36, OT30, S36 or S30. Giving a wide range of vibration forces and amplitudes to suit the vibration requirements.

Advantages of Dense Phase Conveying over Lean Phase Conveying

Filquip Pty Ltd Australia : March 2025

Advantages of Dense Phase Conveying over Lean Phase Conveying

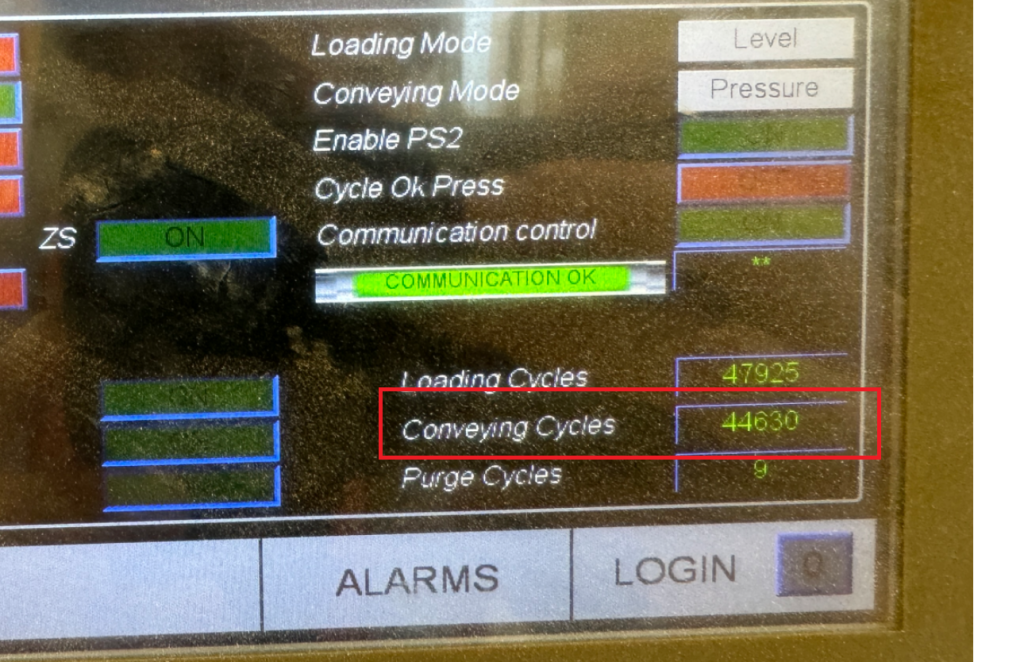

It’s been just over five years since Filquip supplied and commissioned a Stainless Steel 304 Air-Tec Systems 1500L 12TPA500 Dense Phase Conveyor for transporting Animal Feed Minerals, complete with a Dense Phase Diverter Valve and WAM Dust Collectors. During a recent site visit, we checked the Control Panel PLC to see how the system has performed over the past half-decade.

In five years, the unit has completed 44,630 cycles, moving approximately 1,150 kg per cycle. That’s an impressive 51.3 million kg of product conveyed—with only one inlet valve, one diverter valve seal, and two sets of dust collector filters replaced as part of routine maintenance.

When comparing lean phase and dense phase conveying, the higher upfront cost of a dense phase system often stands out. However, the long-term benefits such as minimal maintenance, reduced downtime, and lower energy costs per kg of product conveyed almost always deliver substantial savings over time. In terms of operational lifecycle cost, dense phase conveying consistently proves to be the smarter investment.

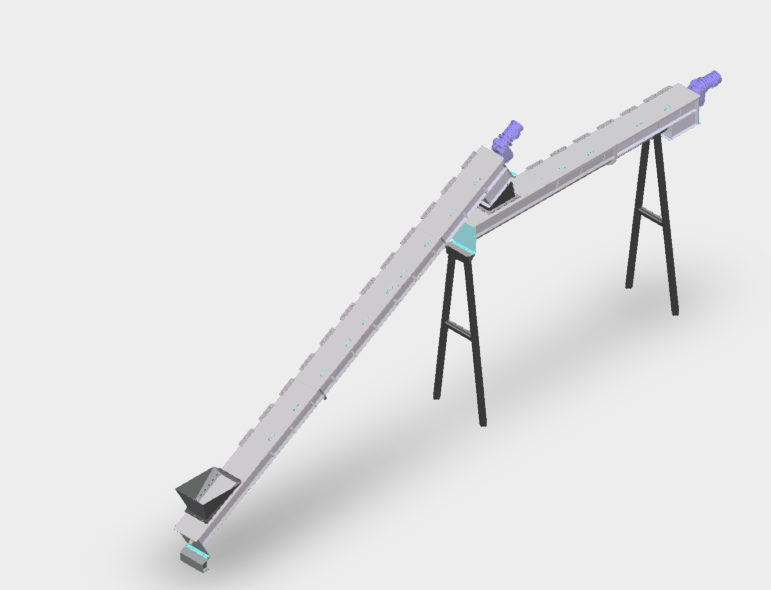

Shaftless Screw Conveyors for Salad and Rockwool

Filquip is proud to work with our local partners we have supplied shaftless screw conveyors for moving salad waste, rockwool and dirt.

Some great photos to show the process Filquip and our fabrication partners go through to deliver a quality a pair of Shaftless Trough Screw Conveyors as a System for handling Waste Salad Products.

Inclined Screw: WAM SSS304 Shaftless Screw conveyor, Model number SSX.F.3.350.7500 4kW

Horizontal Screw: WAM SS304 Shaftless Screw conveyor, Model number SSX.F.3.350.4750 4kW

From 3D Design Modelling, Trial Assembly at the fabricators workshop to completed job onsite.

TOREX Rotary Valves Casting Numbers

Filquip is a proud supplier of TOREX Rotary Valves from Italy. The following table presents some of the casting numbers that appear on the Torex Rotary valves. Please contact Filquip for any Rotary Valve inquiry.

| Rotary Valve Type | Torex Casting Main Number | Torex Casting Main Number | Other Casting Numbers Torex | Other Casting Numbers Torex | Other Casting Numbers Torex |

| RV02 | TOREX 93210 | 93210 | EN GJL 250 | ||

| RV05 | TOREX 93230 | 93230 | EN GJL 250 | ||

| RV10 | TOREX 93239 | 93239 | EN GJL 250 | ||

| RV20 | TOREX 93232 | 93232 | EN GJL 250 | ||

| RVR02 | TOREX 93210 | 93210 | EN GJL 250 | ||

| RVR05 | EN GJL 250 | ||||

| RVR10 | EN GJL 250 | ||||

| RVR20 | EN GJL 250 | ||||

| RVC05 | TOREX 93518 | 93518 | |||

| RVC10 | TOREX 93806 | 93506 | 93522 | 93520 | |

| RVC15 | |||||

| RVC20 | |||||

| RVC35 | TOREX 93560 | 93560 | 93552 | 178223 | 93550 |

| RVC80 | TOREX 93511 | 93511 | 92555 |

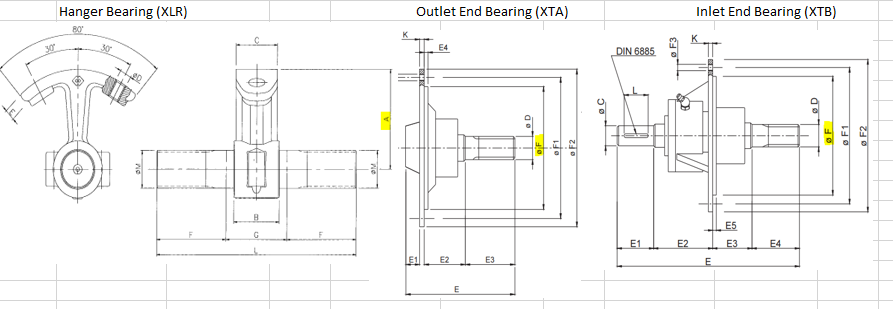

WAM Screw Conveyor Bearings Casting Numbers

Filquip is a supplier of Spare Parts for WAM Screw Conveyors. The bearings on WAM Screw Conveyors including the hanger bearings, Outlet End and Inlet End Bearings can be difficult to navigate with their various casting numbers so we have prepared this list to assist. For all your WAM Equipment spare parts needs please contact Filquip Pty Ltd.

| WAM Screw Conveyor Parts | |||||||||

| Screw | Hanger Bearings | Outlet End Bearings | Inlet End Bearing | ||||||

| Diameter (mm) | Part Number | Casting Number | Length (A) (mm) | Part Number | Casting Number | Length (F) (mm) | Part Number | Casting Number | Length (F) (mm) |

| 114 | XLR028H010T44 | 54 | XTA00ES0A01PS0 | 20900311B | 148 | XTB25ES0B00PSF | WAM064001614 | 148 | |

| 139 | XLR028H012T44 | 66.5 | XTA00ES0A01PS0 | 20900311B | 148 | XTB25ES0B00PSF | WAM064001614 | 148 | |

| 168 | XLR040H015T44 | 90719 | 80 | XTA00ES1A01PS0 | 290032 | 162 | XTB35ES1B00PSF | WAM064001515 | 162 |

| 219 | XLR040H020T44 | 90721 | 105.5 | XTA00ES3A01 | WAM430290034 | 210 | XTB35ES3B00PSF | WAM90024 | 210 |

| 273 | XLR040H025T44 | 90722 | 132.5 | XTA00ES4A01PSO | 265 | XTB35ES4B00PSF | WAM064001518 | 265 | |

| 323 | XLR040H030T44 | 90723 | 157.5 | XTA00ES5A01PSO | WAM430295910 | 315 | XTB35ES5B12 | WAM90026 | 315 |