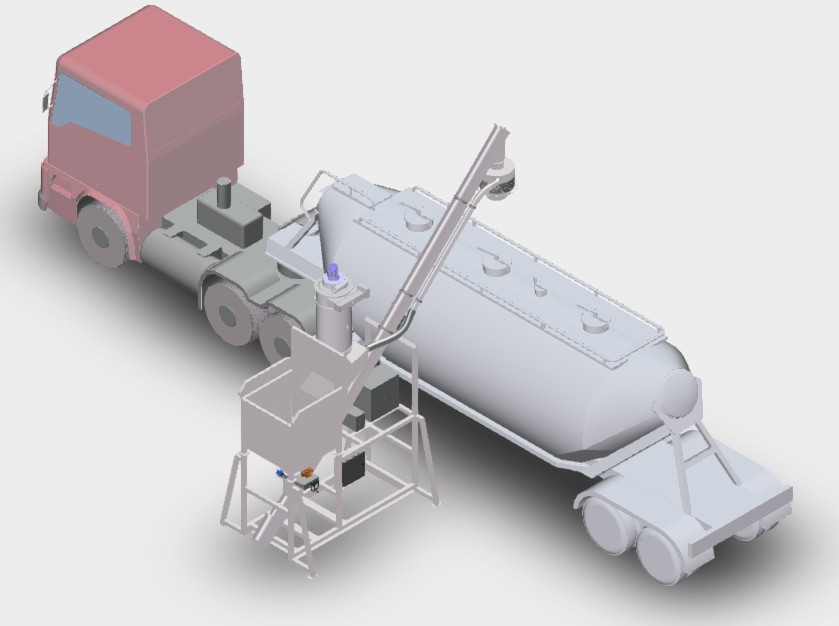

The RSA Automatic bag splitter allows the splitting of bags loaded onto a conveyor belt by pressing and cutting to unload the product in an automatic and safe manner.

The RSA Automatic Bag Splitting Station by EXTRAC is great value, offering cutting edge technology with few moving components and a simple operating principle.

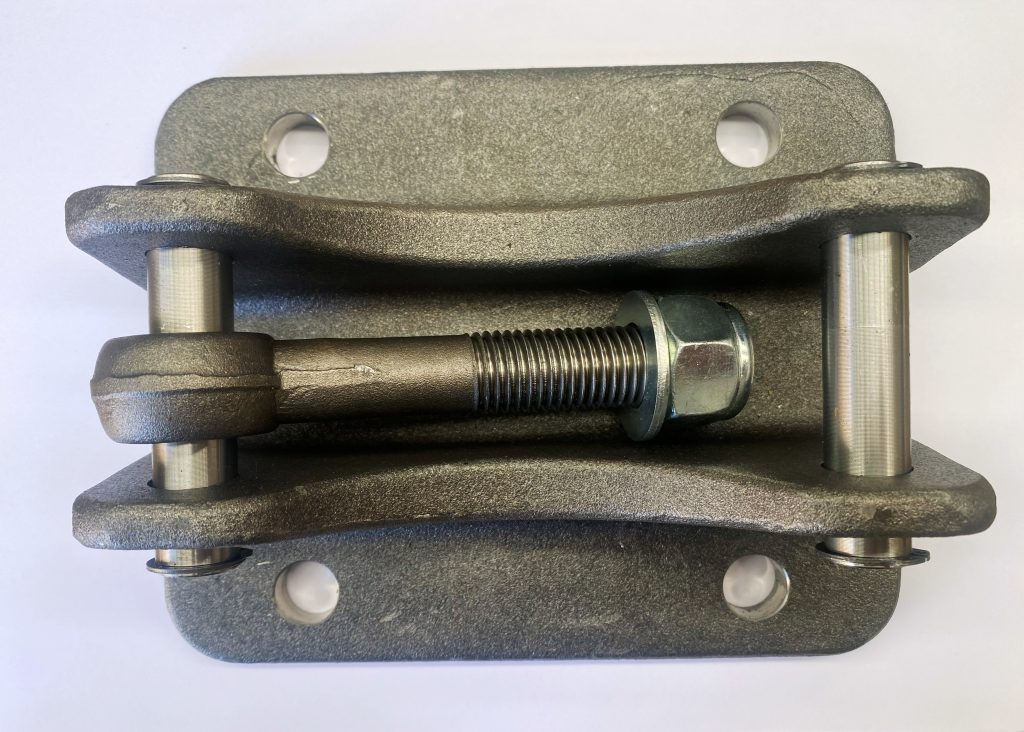

It is made up of a splitting unit which consists of a trough that encloses an extra heavy-duty splitting screw which cuts the bags and empties the product into the screening unit that is a horizontal, cylindrically shaped rotating screen, complete with drive unit. On top of the screening unit a suitable fan-operated dust collector can be integrated. Alternatively, the RSA is supplied with connecting spigots for a central de-dusting unit.

The RSA Automatic Bag Splitter is used for splitting and emptying of single or multiple layer bags made from paper, polyethylene, polyethylene-lined paper, interwoven plastic, or polyethylene-lined interwoven plastic.

The bags are loaded manually or via a belt conveyor into the inlet which is covered by a dust collection hood. The bags drop from the belt on a heavy-duty shaftless screw. Thin bags will burst open just through impact. Bags with multiple layers or those made of elastic plastic material are pulled in by the slowly turning screw and ripped open through a scissor effect between screw and trough. Interwoven plastic bags are cut open by a multiple cutting disc set mounted on top of the inlet. The bag contents fall through the screen mesh into a collecting device mounted on the outlet of the machine allowing the product to be fed into a Screw Conveyor, Rotary Valve or other conveying system.

- Available in Carbon Steel, Stainless Steel 304 or Stainless Steel 316.

- Available with duct collection filter mounted on the unit.

- Available with connection for a centralised dust collection system to be connected.

- Low operating noise.

- Able to handle bags of different sizes without machine adjustment.

- Low product residue.

Open Automatic Bag Break Station Brochure