Filquip has a range of vibrator mounting channels and plates with pre-set studs or tapped holes to suit a range of vibrators.

Filquip has a range of vibrator mounting channels and plates with pre-set studs or tapped holes to suit a range of vibrators.

Open Pneumatic Vibrator Channel Mount Brochure

Open Electric Vibrator Channel Mount Brochure

Open Impact Hammer Vibrator Mounting Plate Brochure

MagBase Magnetic Vibrator Mounting Bracket

The Filquip MagBase is a magnetic vibrator mounting bracket that allows the user to apply vibration from an OR100, OT36S, OT36, OT30, S36 or S30 Pneumatic Vibrator to any ferromagnetic metal (Iron, Steel, Cobalt, Nickel).

The Filquip MagBase magnetic vibrator mounting bracket is made from Stainless Steel 304 and uses strong rare earth magnets to hold the vibrators against the steel formwork, hopper walls, silos or bins requiring vibrating.

- Great for testing the optimal position to mount a vibrator before permanent installation.

- Ideal for moving around concrete moulds as they are easily detachable.

- Heavy Duty build for operations where the magnetic vibrator setup will be constantly moved and the pneumatic connections need protection from being knocked.

- Strong rare earth magnets hold the vibrator to the wall of the bin, hopper, silo or frame.

Open MagBase Brochure

Oli Vibrator Clamps and Cradles

Oli Vibrator Clamps and Cradles

Vibrator clamps and cradles are ideal for positioning vibrators on formwork in permanent locations while still being able to detach the vibrator and move it between forms, saving costs on vibrators.

- CLW series as a clamp for wooden form works.

- CLS series as a clamp for steel form works.

- CRS series as a weld-on cradle for steel concrete moulds.

Open Oli Vibrator Clamp Brochure

Filquip has a range of vibrator mounting channels and plates with pre-set studs or tapped holes to suit a range of vibrators.

Filquip has a range of vibrator mounting channels and plates with pre-set studs or tapped holes to suit a range of vibrators.

Oli Vibrator Clamps and Cradles

Oli Vibrator Clamps and Cradles

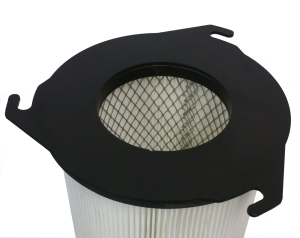

Replacement DCE Unicell and Other Dust Collector Filters

Replacement DCE Unicell and Other Dust Collector Filters

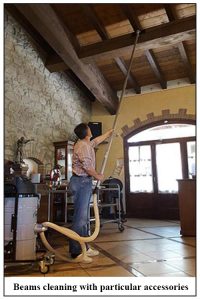

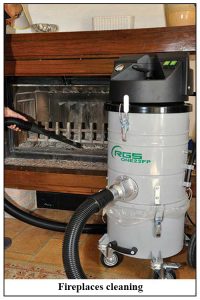

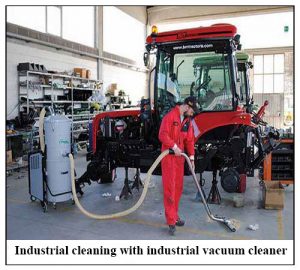

Our Filquip / RGS industrial vacuum cleaners are suitable for general cleaning in industrial environments and premises. Built to handle vacuuming of wet and dry products the One range of units are Practical, Easy to handle and Quiet in operation. The design of the whole unit has been economised to reduced dimensions in order to meet the space requirements of operation in industrial premises and for storage.

Our Filquip / RGS industrial vacuum cleaners are suitable for general cleaning in industrial environments and premises. Built to handle vacuuming of wet and dry products the One range of units are Practical, Easy to handle and Quiet in operation. The design of the whole unit has been economised to reduced dimensions in order to meet the space requirements of operation in industrial premises and for storage.