Filquip has been providing dust free loading be llows (Also known as loading spouts or loading chutes) for silo discharging systems for over 18 years for all types of powders and granular materials.

llows (Also known as loading spouts or loading chutes) for silo discharging systems for over 18 years for all types of powders and granular materials.

The various models of Loading Bellows Filquip supply include models for ship loading and ship unloading, tanker truck loading, open truck loading and stock piling.

View the loading Bellow Specifications Datasheet and brochure

TOREX ZH Open Truck Loading Bellows

The TOREX ZH Open Truck telescopic loading bellows model has been developed to provide a dust free chute to discharge dry, dusty bulk solids into open trucks or lorries.

The TOREX ZH Open Truck telescopic loading bellows model has been developed to provide a dust free chute to discharge dry, dusty bulk solids into open trucks or lorries.

The ZH Loading Bellows are used for efficient, dust-controlled discharging of dry, dusty bulk solids. This type of loading spout is provided with inner cones to contain the flow of material and an outer bellows to contain and channel the dust for removal to a centralised dust collector. The stroke of the bellows comes in a range of sizes to suit almost any truck size, silo height or other site variable.

Firstly the Loading Bellows are lowered from their retracted position down to the truck bed. As soon as the bellows outlet touches the truck bed, a slack cable switch mounted outside the transmission box stops lowering of the bellows. A limit switch inside the transmission box stops both full extension and contraction of the bellows. Material loading starts by opening the silo outlet valve to flow through the chute, retracting it as the product pile fills under the head of the bellows.

Once the bellows is fully retracted, the cable limit switch inside the transmission box stops operating.

- ZH Standard inlet diameter of 300mm (12 inch) or ZK High capacity diameter of 400mm (16 inch).

- ZH Standard throughput capacity up 250m³ / hr (147 CFM) and ZK high throughput capacity up 440m³ / hr (260 CFM).

- ATEX Zone 20-22 and 20-21 versions available.

- Operating temperatures from -40°C to 150°C.

- Solid flange for centralised dust suction.

- Lifting cables are located outside of the material flow to avoid and wear or flow obstruction.

- Available with single wall bellows or double wall bellows in Neoprene-hypalon, Polyester or Kevlar.

- Control Panel, Junction Box and Remote Control Pendant options.

Open ZH Open Truck Loading Bellows Brochure

TOREX ZG Tanker Loading Bellows

The TOREX ZG Tanker Truck telescopic loading bellows range has been developed to provide a dust free spout which discharges dry, dusty bulk solids into tanker trucks, isotainers and convair trucks.

The TOREX ZG Tanker Truck telescopic loading bellows range has been developed to provide a dust free spout which discharges dry, dusty bulk solids into tanker trucks, isotainers and convair trucks.

The ZG Loading Bellows are used for efficient, dust-controlled discharging of dry, dusty bulk solids. The loading spout is provided with inner tapered cones to contain the flow of material and an outer double bellows to provide for the dust path. A solid connection to a centralised filter unit ensures dust-free operation. The stroke of the bellows comes in a range of sizes to suit almost any tanker size, silo height or other site variable.

At the lower end of the Loading Bellows, a SINT engineering polymer-coated cone with special sealing properties is provided for connection to the tanker.

During operation the Loading Bellows are lowered from their retracted position down to the tanker inlet spout. As soon as the bellows outlet cone touches the tanker inlet, a slack cable switch mounted outside the transmission box stops lowering of the bellows. A limit switch inside the transmission box stops both full extension and contraction of the bellows. During filling, the polymer coating of the outlet cone provides the perfect dust seal while the slack cable limit switch controls lowering the bellows onto the tanker to keep the seal as the tanker lowers under the weight of the product.

- ZG Standard inlet diameter of 300mm (12 inch) or ZJ High capacity diameter of 400mm (16 inch).

- ZG Standard throughput capacity up 250m³ / hr (147 CFM) and ZJ high throughput capacity up 440m³ / hr (260 CFM).

- ATEX Zone 20-22 and 20-21 versions available.

- Operating temperatures from -40°C to 150°C.

- Solid flange for centralised dust suction.

- Lifting cables are located outside of the material flow to avoid and wear or flow obstruction.

- Reverse cone with inside level control indicated with the tanker is full.

- Available with single wall bellows or double wall bellows in Neoprene-hypalon, Polyester or Kevlar.

- Control Panel, Junction Box and Remote Control Pendant options.

Open ZG Tanker Truck Loading Bellows Brochure

TOREX ZX Ship and Stockpile Loading Bellows

The TOREX ZX Ship and Stockpile telescopic loading bellows range has been developed for efficient dust free loading of ships and unloading to stockpile of powders and granular materials.

The TOREX ZX Ship and Stockpile telescopic loading bellows range has been developed for efficient dust free loading of ships and unloading to stockpile of powders and granular materials.

The ZX Loading Bellows are used for efficient, dust-controlled discharging of dry, dusty bulk solids. This type of loading spout is provided with inner cones to contain the flow of material and an outer bellows to contain and channel the dust for removal.

During operation the Loading Bellows are lowered from their stand-by position down towards the ship hold or stockpile. When the bellows outlet touches the ground, a slack cable switch mounted outside the transmission box stops lowering of the bellows. The limit switch inside the transmission box stops both the full extension and contraction of the bellows. Material loading starts by opening the silo outlet valve.

Once the loading chute is fully contracted, the cable limit switch inside the transmission box stops operation.

- Inlet diameter of 500mm (20 inch).

- Throughput capacity up 850m³ / hr (500 CFM)

- ATEX Zone 20-22 and 20-21 versions available.

- Operating temperatures from -40°C to 150°C.

- Offers excellent dust free outloading due its its specifically designed bottom skirt.

- Lifting cables are located outside of the material flow to avoid and wear or flow obstruction.

- Available with single wall bellows or double wall bellows.

- Control Panel, Junction Box and Remote Control Pendant options.

Open ZX Ship Unloading Bellows Brochure

TOREX ZQ High Capacity Loading Chutes

The TOREX ZQ High Capacity Ship and Stockpile telescopic loading chutes range have been developed for efficient dust free loading of ships, barges or stockpiling.

The TOREX ZQ High Capacity Ship and Stockpile telescopic loading chutes range have been developed for efficient dust free loading of ships, barges or stockpiling.

The ZQ Loading Chutes are used for efficient, dust-controlled discharging of dry, dusty bulk solids. This type of loading chute is provided with inner cones for channeling the material flow and an outer bellows to contain and channel the dust for removal via an external dust collector.

- Inlet diameter of 800mm (32 inch).

- Throughput capacity up 1,800m³ / hr (1,060 CFM)

- Operating temperatures from -20°C to 150°C.

- Maximum extension 30m

- Offers excellent dust free outloading due its its specifically designed bottom skirt.

- Lifting cables are located outside of the material flow to avoid and wear or flow obstruction.

- Control Panel, Junction Box and Remote Control Pendant options.

Open ZQ High Capacity Loading Chutes Brochure

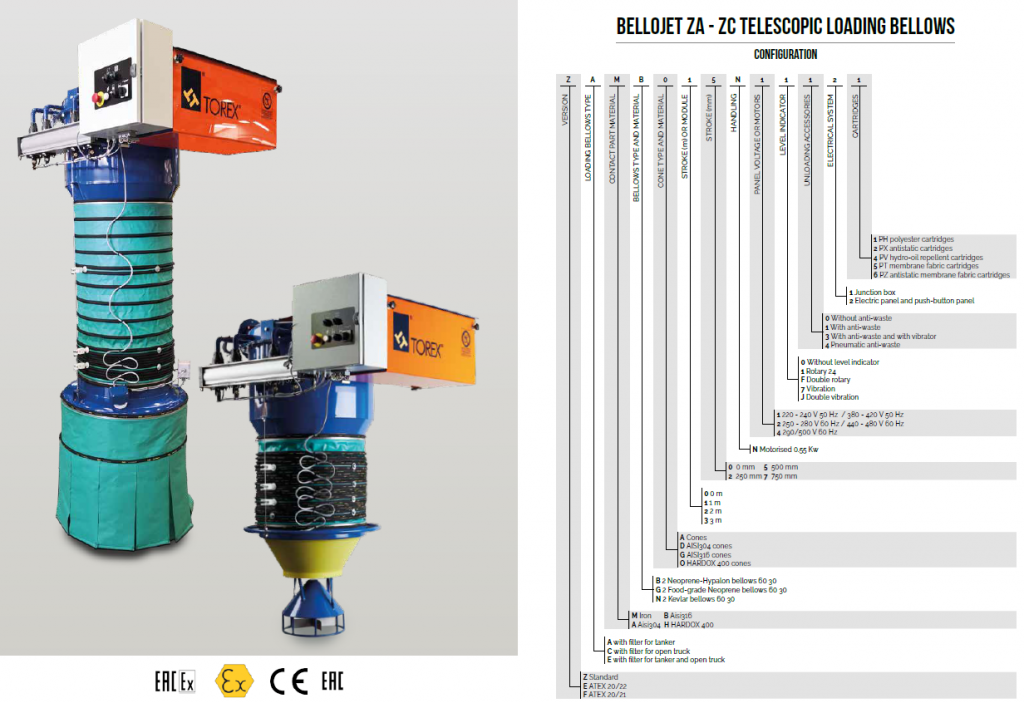

Bellojet ZC Open Loading Bellows with Integrated Dust Collector

The Bellojet ZC Open Truck telescopic loading bellows with integrated Dust Collector model has been developed to provide a dust free chute to discharge dry, dusty bulk solids into open trucks or lorries.

The Bellojet ZC Loading Bellows are used for efficient, dust-controlled discharging of dry, dusty bulk solids. This type of loading spout is provided with inner cones to taper the flow of material and an outer bellows to contain and channel the dust up into its integrated dust collector. The stroke of the bellows comes in a range of sizes to suit almost any truck size, silo height or other site variable.

Firstly the Loading Bellows are lowered from their retracted position down to the truck bed. As soon as the bellows outlet touches the truck bed, a slack cable switch mounted outside the transmission box stops lowering of the bellows. A limit switch inside the transmission box stops both full extension and contraction of the bellows. Material loading starts by opening the silo outlet valve to flow through the chute, retracting it as the product pile fills under the head of the bellows. Contraction of the bellows back to stand-by position is started by the operator via remote control.

During filling of the truck the integrated dust collector fan continuously draws dust through the external bellows into the filter cartridges in the upper section of the unit. Once the bellows are fully retracted the shut down pulse jet cleaning cycle runs for another ten minutes.

- ZC Standard inlet diameter of 300mm (12 inch).

- ZC Standard throughput capacity up 250m³ / hr (147 CFM)

- ATEX Zone 20-22 and 20-21 versions available.

- Operating temperatures from -40°C to 150°C.

- Integrated Dust Collector Filter Surface Area of 10m2

- Lifting cables are located outside of the material flow to avoid and wear or flow obstruction.

- Available with single wall bellows or double wall bellows in Neoprene-hypalon, Polyester or Kevlar.

- Control Panel, Junction Box and Remote Control Pendant options.

Open Bellojet ZC Open Truck with Integrated Dust Collector Loading Bellows Brochure

Bellojet ZA Tanker Truck Loading Bellows with Integrated Dust Collector

The Bellojet ZA Tanker Truck telescopic loading bellows with integrated Dust Collector model is ideal for providing a dust free spout to discharge dry, dusty bulk solids into tankers.

The Bellojet ZA Loading Bellows are used for efficient, dust-controlled discharging of dry, dusty bulk solids. This type of loading spout is provided with inner cones to taper the flow of material and an outer bellows to contain and channel the dust up into its integrated dust collector. The stroke of the bellows comes in a range of sizes to suit almost any truck size, silo height or other site variable.

At the lower end of the Loading Bellows, a SINT engineering polymer-coated cone with special sealing properties is provided for connection to the tanker.

Firstly the Loading Bellows are lowered from their retracted position down to the tanker inlet. As soon as the outlet cone settles on the inlet spout of the tanker, a slack cable switch mounted outside the transmission box stops lowering of the bellows. A limit switch inside the transmission box stops both full extension and contraction of the bellows. Material loading starts by opening the silo outlet valve to flow through the chute, retracting it as the product pile fills under the head of the bellows.

During filling of the truck the integrated dust collector fan continuously draws dust through the external bellows into the filter cartridges in the upper section of the unit. Contraction of the bellows back to the standby position starts after a delay of approximately ten seconds in order to allow the filter to evacuate the remaining dust. The preset shut down pulse jet cleaning cycle runs for another ten minutes after the bellows are fully retracted, and the dust then is contained by the bellows closure cone.

- ZA Standard inlet diameter of 300mm (12 inch).

- ZA Standard throughput capacity up 250m³ / hr (147 CFM)

- ATEX Zone 20-22 and 20-21 versions available.

- Operating temperatures from -40°C to 150°C.

- Integrated Dust Collector Filter Surface Area of 10m2

- Lifting cables are located outside of the material flow to avoid and wear or flow obstruction.

- Closure cones provides anti-spillage operation.

- Available with single wall bellows or double wall bellows in Neoprene-hypalon, Polyester or Kevlar.

- Control Panel, Junction Box and Remote Control Pendant options.

Open Bellojet ZA Tanker Truck with Integrated Dust Collector Loading Bellows Brochure

TOREX ZN Manual Loading Bellows

The TOREX ZN Loading bellows range are the economic solution for controlled outloading of materials.

The TOREX ZN Loading bellows range are the economic solution for controlled outloading of materials.

The ZN Manual Winch Operated Loading Bellows are provided with a single telescopic bellows chute and at the lower end a sealing cone is provided for connection to the tanker inlet

- Inlet diameter of 300mm (12 inch).

- Throughput capacity up 250m³ / hr (147 CFM)

- ATEX Zone 20-22 and 20-21 versions available.

- Operating temperatures from -40°C to 150°C.

- Various chute materials available.

- Includes manual winch with transmission.

- Control Panel, Junction Box and Remote Control Pendant options.

Bellojet ZN Manual Loading Bellows Brochure

Minifill ZM Loading Bellows for Drums & IBCs

The TOREX MINIFILL ZM is the perfect choice for dust-free loading of bulk solids into drums or IBCs where space is limited.

The TOREX MINIFILL ZM is the perfect choice for dust-free loading of bulk solids into drums or IBCs where space is limited.

Two pneumatic cylinders provide the pressure to seal the outlet head onto the vessel being filled and the ability to order with a double bellows design allows the suction fan rate can be increased when operating with very fine dust.

- Inlet diameter of 200mm (12 inch).

- Throughput capacity up 120m³ / hr (70 CFM)

- Operating temperatures from -15°C to 120°C.

- Offers excellent dust free outloading due to the special bottom seal plate design.

- Pneumatically operated.

- Available with single wall bellows or double wall bellows.

- Various chute materials available.