Filquip supplies a large range of Torex Rotary Valves for all metering, feeding and airlock applications. Torex rotary valves are suitable for pneumatic conveying, dust collector air locks, product feed control and metering and many other applications.

View the Rotary Valves specifications datasheet and brochure

Rotary valves are also known as Rotary seals and Air Locks.

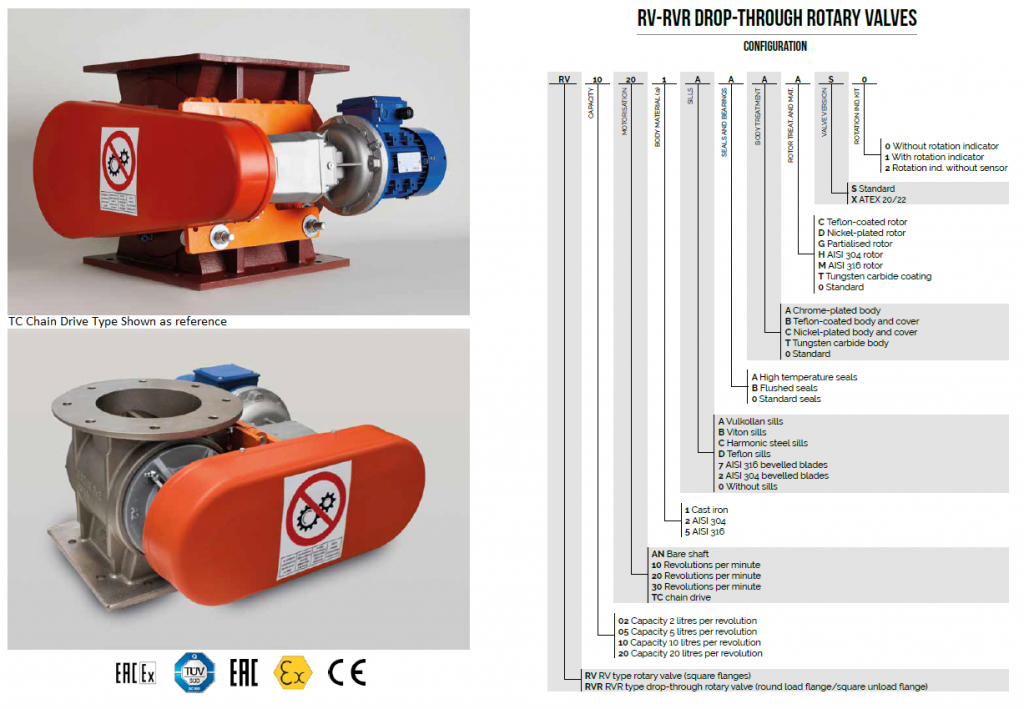

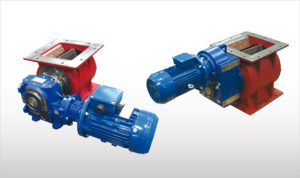

RV / RVR Rotary Valve – Standard Drop Through Model

RV / RVR Rotary Valve – Standard Drop Through Model

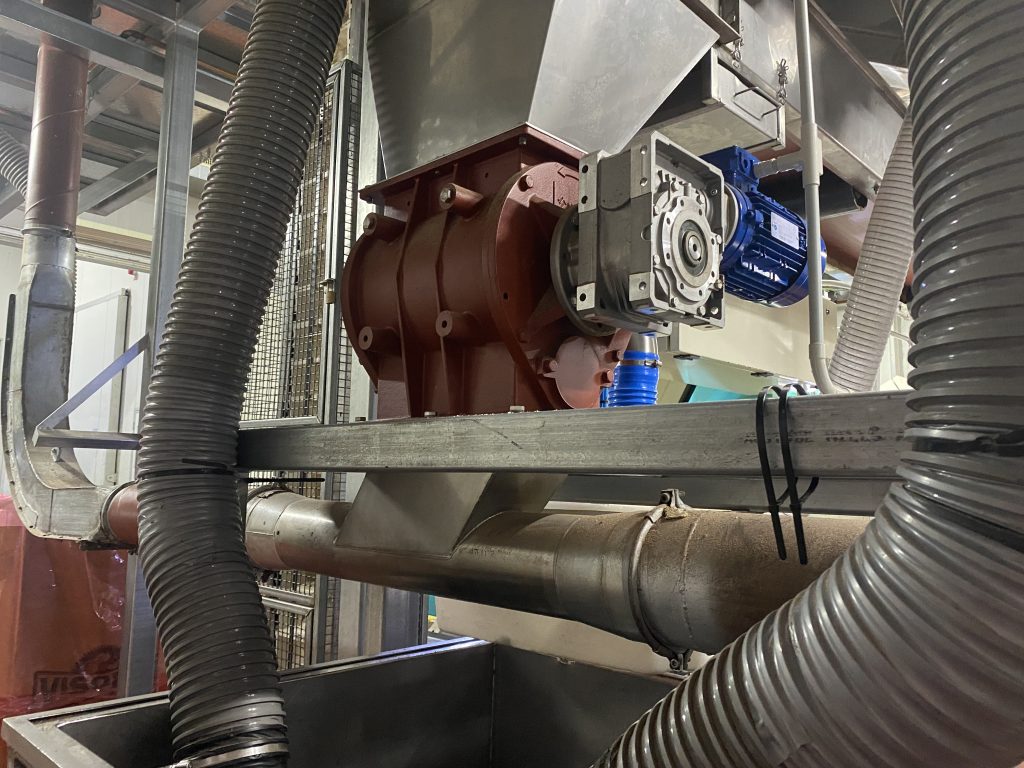

Filquip provides a range of TOREX RV / RVR drop through rotary valves with are available with square or round inlets. They are the ideal solution for providing an airlock or controlled feed/discharge of powder or granular materials from silos, hoppers, pneumatic conveying systems, bag filter houses, or cyclones.

The RVS Blow-Through Rotary Valves consist of a tubular cast iron or stainless steel casing, a horizontally mounted rotor with a certain number of oblique V-shaped cross section compartments, a drive unit and a casing cover at each end.

- Maximum differential pressure 0.3 bar (4.4 PSI).

- Available in Cast iron, Stainless Steel 304 & 316, Chrome Bore, Teflon and Nickel plated options.

- Available with Tungsten Carbide Coating for extreme abrasion resistance.

- Round inlet diameters of 150,200,250 & 300mm.

- Square inlet dimensions of 150,200,250 & 300mm.

- Capacities of 5, 10, 15, & 20 L/Rev

- Working Temperatures from -40°C to + 150°C

- Available in Hazardous Zone Rated configurations and Flame Proof Versions.

- Options for Air-Purged Seals, External Bearings, Scraps Tips and Chain Drive Units

Open RV / RVR Rotary Valve Brochure

RVS Rotary Valve – Blow Through Model

RVS Rotary Valve – Blow Through Model

Filquip provides a range of TOREX RVS blow through rotary valves with oblique V-Shaped rotor pockets to meter solids from a hopper or silo and place into a blower pneumatic conveying system.

The RVS Blow-Through Rotary Valves consist of a tubular cast iron or stainless steel casing, a horizontally mounted rotor with a certain number of oblique V-shaped cross section compartments, a drive unit and a casing cover at each end.

- Maximum differential pressure 0.8 bar (11.6 PSI)

- Available in Cast iron, Stainless Steel 304 & 316, Chrome Bore, Teflon and Nickel plated options.

- Available with Tungsten Carbide Coating for extreme abrasion resistance.

- Rectangular inlet dimensions of 170×122, 238×135, 276×148, 377×196, 470×240 & 569x284mm.

- Capacities of 5, 10, 15, 20, 35 & 80 L/Rev.

- Working Temperatures from -40°C to + 220°C

- Available in Hazardous Zone Rated configurations and Flame Proof Versions.

- Options for Air-Purged Seals, External Bearings, Scraps Tips and Chain Drive Units

Open RVS Rotary Valve Brochure

RVC Rotary Valve – Bent Rotor Drop Through

RVC Rotary Valve – Bent Rotor Drop Through

Filquip provides a range of TOREX RVC drop through rotary valves with oblique V-Shaped rotor pockets for high efficiency accurate feeding of powders and granules.

Through the top inlet two rotor compartments at a time are filled as the rotor continuously turns. After less than half a rotation the material falls through the bottom outlet opening having the same cross section as the opposite inlet.

- Maximum differential pressure 0.7 bar (10.1 PSI)

- Available in Cast iron, Stainless Steel 304 & 316, Chrome Bore, Teflon and Nickel plated options.

- Available with Tungsten Carbide Coating for extreme abrasion resistance.

- Rectangular inlet dimensions of 170×122, 238×135, 276×148, 377×196, 470×240 & 569x284mm.

- Capacities of 5, 10, 15, 20, 35 & 80 L/Rev.

- Working Temperatures from -40°C to + 220°C

- Available in Hazardous Zone Rated configurations and Flame Proof Versions.

- Options for Air-Purged Seals, External Bearings, Scraps Tips and Chain Drive Units

Open RVC Rotary Valve Brochure

The bent rotor RVC series are ideal for Pneumatic conveying systems when combined with a Filquip designed Venturi adaptor.

RWN Rotary Valve – Wood chips & Pellets

RWN Rotary Valve – Wood chips & Pellets

The TOREX RWN rotary valve is ideal for the controlled feeding/discharging of wood pellets or chips from silos, hoppers, pneumatic conveying systems, bag filter houses, or cyclones.

The RWN Drop-Through Rotary Valve with square inlet consists of a tubular casing with horizontally mounted rotor of four V-shaped cross section compartments. It is manufactured from wear-resistant HARDOX steel including the sill on the inlet to ensure the cutting of chips into the valve.

The Rotary Valve is equipped with a direct drive. The plate opposite the drive end has an externally placed roller bearing which does not come into contact with the material. The bearing provides high resistance to stress and radial loads.

- Square inlet dimensions of 150,200,250 & 300mm.

- Capacities of 5, 10, 15, & 20 L/Rev

- Working Temperatures from -20°C to + 150°C

- Designed in accordance with wood fuel as per ONORM M7132, ONORM M7133 and ONORM M7135 Standards.

Open RWN Rotary Valve Brochure