Filquip supplies the full range of WAM Slide Gate Valves for handling powder and granular materials. They are the perfect solution for isolating or intercepting material flow out of hoppers, silos and bins. Suitable for all industrial sectors and the food industry.

WAM Slide Gate Valves – VL Series

WAM Slide gate valves are used where the flow of a bulk solid by gravity is required to be intercepted.

WAM Slide gate valves are used where the flow of a bulk solid by gravity is required to be intercepted.

VL-type WAM Slide Gate Valves consist of a two-piece carbon or stainless steel frame partly coated with polymer composite. They have a sliding blade manufactured from SINT engineering polymer, carbon steel or stainless steel. The use of the unique SINT engineering polymer composites considerably increases resistance to abrasion as compared to traditional valves. Moreover, it avoids the use of flange gaskets.

The specific geometry of the VL Slide Gate Valves and the various options in blade design enable their application in virtually all industries including food processing.

- Carbon steel and Stainless steel construction material options.

- All around dust proof seal lip integrated into polymer coating resulting in no need for gaskets.

- VLQ Series – Square cross section sizes of 150×150, 200×200, 250×250, 300×300, 350×350 & 400x400mm.

- VLC Series – Round cross section diameters of 150, 200, 250, 300, 350 & 400mm.

- VLR Series – Rectangular cross section sizes of 200×120, 280×170, 350×220, 430x270mm.

- VLS Series – Square cross section with Internal Actuation.

- Manual, Pneumatic or Electrical Actuation options available.

- Hazardous Area Certified Options Available.

Open VL Series Slide Valve Brochure

WAM Slide Gate Valves – Large VG Series

WAM Slide gate valves are used where the flow of a bulk solid by gravity is required to be intercepted.

WAM Slide gate valves are used where the flow of a bulk solid by gravity is required to be intercepted.

VG-type Slide Valves are entirely manufactured from carbon steel or stainless steel and have excellent durability which is guaranteed. This type of valve is designed to meet the most demanding applications when handling abrasive materials such as sand, gravel, coal, or whole grain in heavy duty applications. They are equipped with two replaceable, abrasion-resistant seals and are available in various configurations.

- Carbon steel and Stainless steel construction material options.

- Ledge free design stops material from building up and minimises cross contamination and spoilage.

- VG Series – Square cross section sizes of 500×500, 600×600, 700×700, 800×800 & 1000x1000mm.

- VGR Series – Rectangular cross section sizes of 150×250, 200×300, 250×400, 300×450, 375×560 & 425x650mm.

- Manual, Pneumatic or Electrical Actuation options available.

- Food grade versions available.

Open VG Slide Gate Valves Brochure

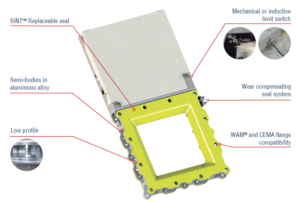

VIB Low Profile Slide Gate Valves

The WAM VIB Low Profile Slide Gate Valve is a low profile cost effective solution for isolating powders and granular materials in hoppers, bins and silos.

The thin valve consists of two high pressure die-cast semi-bodies manufactured from aluminium alloy, a sliding blade in carbon or stainless steel, a carbon or stainless steel frame with polymer seal. The use of SINT engineering polymer seal considerably reduces the abrasion wear compared to traditional valves. For the food industry they come in a version with stainless steel blade and frame, as well as food-grade seal.

- Dust Proof Sealing.

- VIBQ Series – Square cross section sizes of 150×150, 200×200, 250×250, 300×300, 350×350 & 400x400mm.

- VIBC Series – Round cross section diameters of 150, 200, 250, 300, 350 & 400mm.

- 75mm Flange to Flange (Low Profile)

- Available with Handwheel Actuation, Pneumatic Actuation or Electro-motor actuation.

- Ready to use for horizontal or vertical mounting.