Filquip was engaged by an engineering contractor to specify and supply a dust extractor for a belt transfer point at a quarry following a Barmac crusher. The transfer point between the belt conveyors generated dust clouds after the rocks had been crushed by the Barmac unit releasing dust.

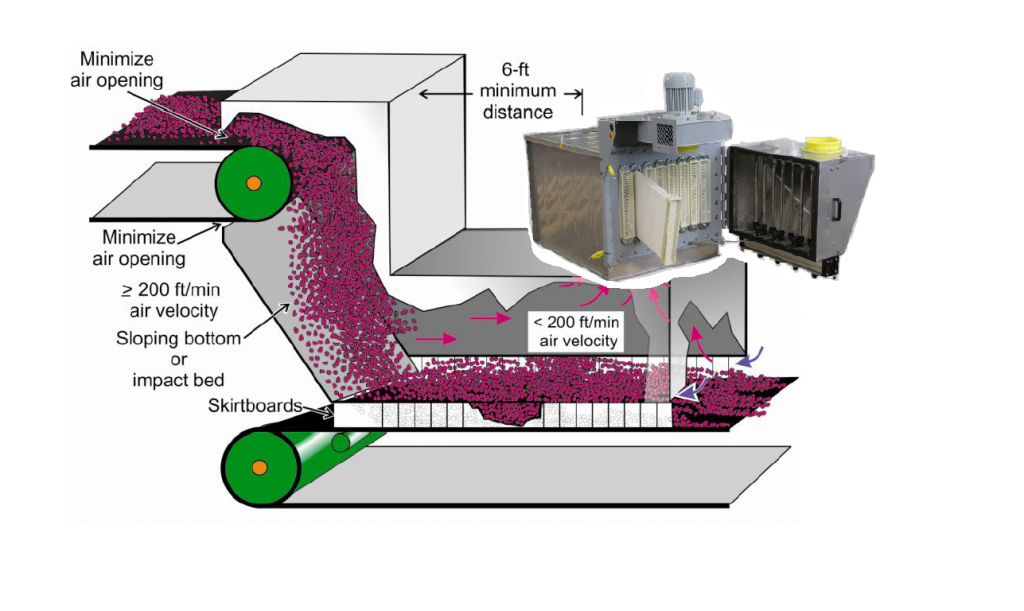

Filquip specified and supplied a FPHT.R.24 Filter Bag Dust Extractor with 4kw Fan Motor which was mounted on the belt transfer point to extract the dust generated and agglomerate it to larger/heavier particle sizes and return it to the belt. The covering of the belt conveyor back to the Barmac Crusher creates a suction funnel to draw dust down through the crusher and into the Dust Extractor.

Filquip is a supplier of Insertable Dust Collectors for Belt Conveyors, the low profile nature of the Insertable unit makes it perfect for mounting on Belt Conveyor systems. Filquip is happy to calculate and specify the dust collector required for Dust Control of your Belt Conveyor.

Filquip is a supplier of Insertable Dust Collectors for Belt Conveyors, the low profile nature of the Insertable unit makes it perfect for mounting on Belt Conveyor systems. Filquip is happy to calculate and specify the dust collector required for Dust Control of your Belt Conveyor.