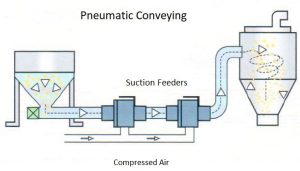

Filquip has developed a Wand Vacuum Conveyor System to vacuum transfer powders and granules from Bags and Trays up into a Discharge hopper to fill into processes as required.

The FVC wand vacuum conveyor can lift almost any powder or granule product from bags, trays or containers and conveys it up into its hopper head unit. The system then discharges the product from the head hopper into any process as required by the customer.

Many processes involve staff lifting heavy bags or drums of powder or granules into equipment. This exposes them to physical injury through incorrect lifting techniques or just lifting things that are too heavy. One of the easiest ways to mitigate this risk is to use vacuum conveying to lift the powder or granules up into the equipment.

- Manufactured from polished 304 stainless steel.

- Food grade suction hose (Suitable for food and pharmaceutical industries).

- The unit comes on lockable wheels for mobility around the facility.

- The unit comes complete with in-built reverse pulse cleaning.

- Simple control panel provided for ease of operator use.

- Discharge height up to 2m.

- Nominal throughput up to 6m3/hr for the largest models.

- Available in Single Phase, Three Phase and Pneumatic motor configurations.

Open FVC Portable Vacuum Conveyor Brochure