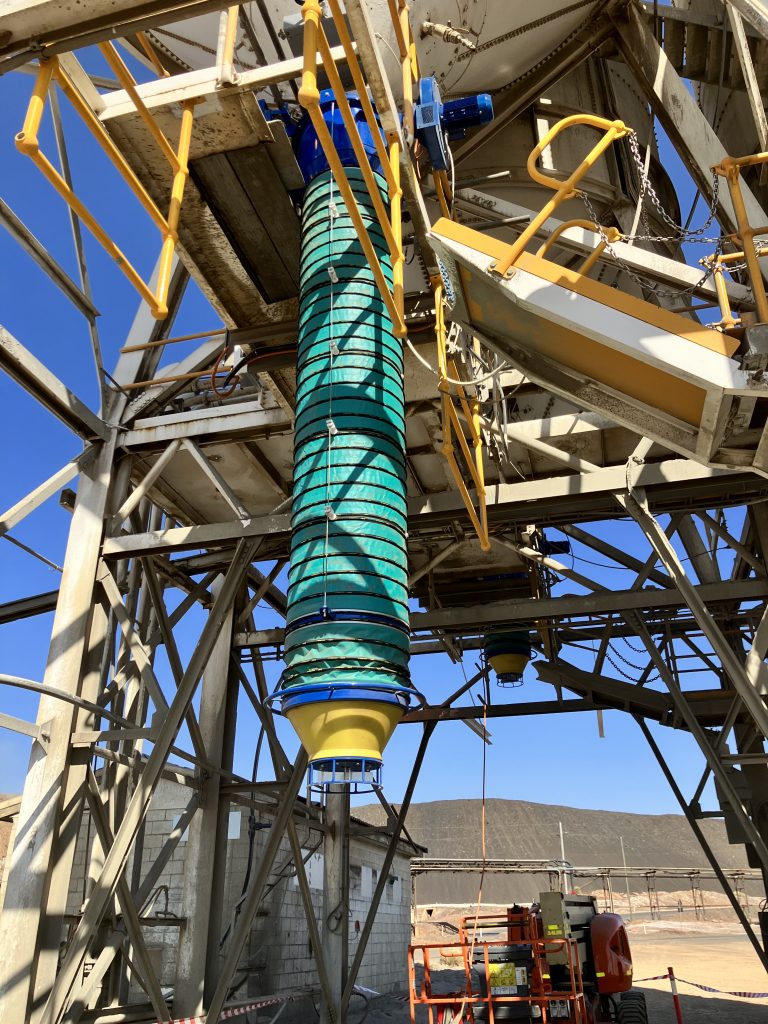

Filquip has completed the Design, Supply and Commissioning for a set of 4 Loading Bellows for existing cement silos on a mine site. The silos are used for bulk cement storage and they fill into individual isotainers which transport the cement to the underground section of the mine.

The new loading bellows provide a safe way for truck drivers to load the cement into the isotainers as the previous method was a hand operated valve and rubber sock. Drivers can now position their truck with Isotainer on the back under the bellows and use the remote pendant controller to lower the bellows outlet onto the inlet of the isotainer.

The integrated dust extractor ensures there is no dust released during the filling process.

The pneumatic actuated slide gate valve allows the operator to open the flow of product as they wish and shut if off as required along with the integrated level sensing in the loading bellows also automatically shutting off the valve and product flow when the Isotainer is full preventing overfilling and backing up into the chute.

The following specifications were included for the Loading Bellows:

- Qty 4: BellowJet ZAMBA.25 Models with integrated Dust control extractor in the Unit

- 0.55kW Winch Motor and 24v Reverse Pulse Automated Air Filter Cleaning System.

- Integrated Level Indicators for Control Feedback to the Actuated Slide Gate Valve.

- Inner and Outer Bellows system with wear resistant inner cones.

- With anti-spillage closure cone that retracts to close the outlet after filling is completed

- Stroke of 2260mm (4170mm extended length, 1910mm retracted length). 300mm diameter bellow.

- 250 m3/hr Throughput Capacity.